Refractory ceramic fiber board

detail intruduction

Refractory ceramic fiber board is a fiber board-like product with constant strength and hardness that is made by removing the slag of ceramic fiber and mixing it with inorganic binder and organic binder in different proportions, forming by vacuum filtration or mechanical pressure filtration, and drying.

Ceramic fiber board is aluminum silicate fiber board, a kind of refractory material. Even after heating, it maintains good mechanical strength. Compared with fiber blankets and felts, this product is a more rigid and supportive fiber insulation product.

Ceramic itself is fired at high temperature, so it is inherently high temperature resistant, but it is prone to cracking under high temperature baking. After being made into refractory ceramic fiberboard, this shortcoming is completely avoided, and it can be used in various industries.

This kind of plate can easily withstand high temperatures exceeding 1000°C. If you refer to specific data, even lower products can reach a fire resistance of 1260°C. This temperature is enough to melt steel, but this kind of plate can still Stay strong in the fire. If it is a higher-density product, it can withstand high temperatures above 1400°C and can be used in coal-fired boilers.

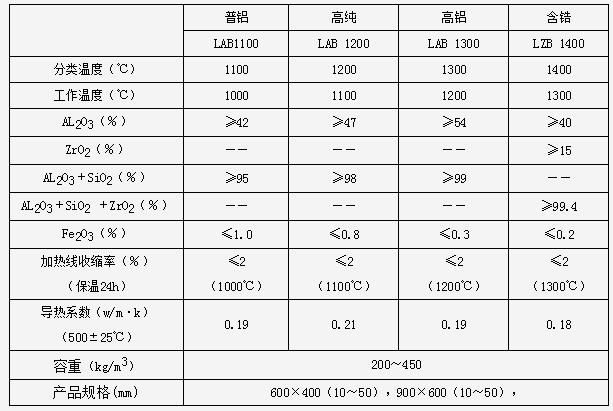

According to the working temperature, the products can be divided into: ordinary aluminum fiber felt (board), standard fiber felt (board), high-purity fiber felt (board), high aluminum fiber felt (board), zirconium-containing fiberboard

The principle of ceramic fiber board production:

Using blown fibers (short, thin, easy to break and mix) as the raw material of ceramic fiberboard, add a certain proportion of binders and filler additives, pass through a beating machine, and fully dispersed into a slurry in the mixing tank. Use a pump to drive into the forming tank and stir with compressed air. Put the mold into the forming tank and use the principle of vacuuming to make the fiber slurry adsorb on the mold. Precisely control the adsorption time, vacuum dehydration of the wet fiber material, demold, put it on the tray and send it to the drying oven to dry for 10-24 hours. The dried fiberboard is accurately controlled in size through the grinder and trimming machine used.

Performance and points:

Ceramic fiberboard not only has excellent properties corresponding to bulk ceramic fiber cotton, the product has a hard texture, excellent toughness and strength, and has excellent wind erosion resistance. It is non-expandable, light in weight, convenient in construction, and can be cut and bent at will. It is an ideal energy-saving material for kilns, pipelines and other thermal insulation equipment.

1. High compressive strength and long service life;

2. Low heat capacity, low thermal conductivity;

3.non-brittle material, good toughness;

4.accurate size, good flatness;

5. Easy to cut and install, convenient for construction;

6. Excellent resistance to wind erosion;

7. Continuous production, uniform fiber distribution and stable performance.

8. Excellent sound absorption.

9. Excellent thermal stability and thermal shock resistance

10.excellent tensile strength

Ceramic fiber board application range:

1. Backing insulation of kilns in cement and other building materials industries;

2. Furnace backing insulation in petrochemical, metallurgy, ceramics, and glass industries;

3. Backing insulation of heat treatment kiln;

4. Backing insulation in non-ferrous metal industry;

5, high temperature reaction, heating equipment backing insulation

6, household appliances heat resistance, heat storage

Product performance:

The previous:Refractory ceramic fiber shaped products The next article:Aluminum silicate fiber cotton