ceramic fiber special shaped products

detail intruduction

Product introduction:

The aluminum silicate refractory fiberboard is made by washing the refractory fiber to remove the ball, and then mixing it with different proportions of inorganic binder and organic binder. The dry or wet vacuum suction filtration molding process is adopted. After special processing, according to different requirements, Different shapes and specifications are made, which are suitable for products with special requirements in different parts.

Features:

Complex shape and strong plasticity;

Easy to install and easy to use;

Excellent fire resistance and thermal insulation performance;

Applications:

Long nozzle sealing ring, pouring different pipe;

Complete set of electrothermal vacuum forming components; Insulation sealing gaskets, gaskets, metal melting grooves, melting groove insulation gaskets;

Various industrial kiln doors, burner bricks, observation holes;

Product advantages:

Aluminum silicate refractory fiber is a relatively new type of refractory insulation material. Statistics show that using aluminum silicate refractory fiber as refractory or thermal insulation material for resistance furnace can save energy consumption by more than 20%, and some as high as 40%. Aluminum silicate fiber has the following advantages.

(1) High temperature resistant ordinary aluminum silicate refractory fiber is an amorphous fiber made of refractory clay, bauxite or high alumina raw materials in a molten state by a special cooling method. The use temperature is generally below 1000 ℃, and some It can reach 1300℃. This is because the thermal conductivity and heat capacity of the aluminum silicate refractory fiber are close to air. It is composed of solid fiber and air, with a porosity of over 90%. Because a large amount of low thermal conductivity air is filled in the pores, the continuous network structure of solid molecules is destroyed, so it has excellent heat resistance and heat preservation performance.

(2) Chemical stability The chemical stability of aluminum silicate refractory fiber mainly depends on its chemical composition and impurity content. This material has very low alkali content, hardly interacts with hot and cold water, and is very stable in an oxidizing atmosphere. However, in a strong reducing atmosphere, impurities such as FeO3 and TiO2 in the fiber are easily reduced, which affects the service life.

(3) Bulk density and thermal conductivity. With different production processes, the bulk density of aluminum silicate refractory fiber varies greatly, generally in the range of 50~500kg/m3. The thermal conductivity is the main indicator to measure the performance of refractory insulation materials. The low thermal conductivity is one of the main reasons why aluminum silicate refractory fiber has better fire and heat preservation performance than other similar materials. In addition, its thermal conductivity is the same as other refractory insulation materials, and it is not constant, and is related to bulk density and temperature.

(4) Simple construction. This refractory material is light in weight and easy to process. After adding the binder, it can be made into various required products. There are also different specifications of felts, blankets and other finished products, which are extremely convenient to use.

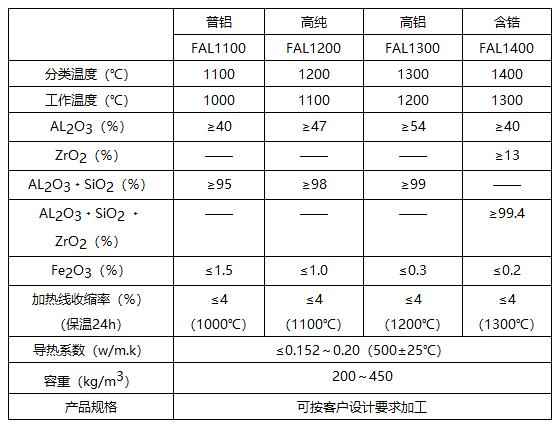

Product performance:

The previous:没有了 The next article:polycrystalline alumina fiber special shaped products