detail intruduction

performance and point

1. High temperature resistance, high temperature resistance

2.High adhesion, strong bonding force with refractory materials

3.high emissivity, infrared emissivity can reach above 0.9

4. Good anti-corrosion performance and long service life

5. The coating has high abrasion resistance, strong impact resistance and scratch resistance

6. Excellent acid and alkali corrosion resistance

7. the coating is cured at room temperature, non-toxic, green and environmentally friendly

8. Low thermal conductivity

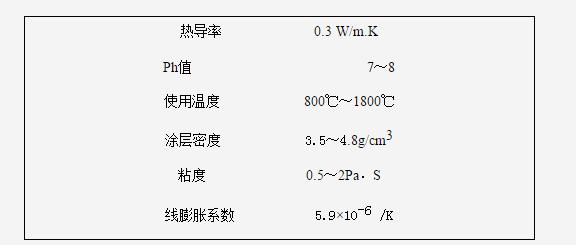

Technical Index

Scope of application

Infrared radiation energy-saving coatings can be applied to the heat-absorbing surfaces of various industrial furnaces and boilers to increase the absorption of furnace flame heat by the furnace lining or boiler tube wall, improve furnace heat exchange conditions, increase thermal efficiency, and achieve energy saving purposes. At the same time, it has a good protective effect on the furnace lining material against high temperature oxidation, prolongs the service life of the furnace and boiler, and reduces the maintenance workload. In addition, by strengthening the radiant heat transfer in the furnace, the temperature uniformity of the thermal field in the furnace and the heating quality of the heated body are improved.

This product not only improves the heat transfer method and process in the industrial furnace with its excellent infrared radiation performance, improves the energy efficiency and production capacity of the industrial furnace, but also protects the lining material, prolongs the service life of the industrial furnace, and reduces production and maintenance. Expenses ultimately achieve the purpose of increasing production, saving energy and reducing production costs. This product can be widely used in kiln refractory linings, and can be constructed on the surface of refractory bricks and refractory fibers. It can be used in ceramic kilns, various heat treatment furnaces, refractory firing kilns, laboratory electric furnaces, etc.

Address: No.43, Xiyuan Road, Luoyang, Henan Province, China.