detail intruduction ¡¡¡¡

Polycrystalline Alumina Fiber Module-cuted is from polycrystalline alumina fiber by special process finishing cutting, compression formed. Does not contain any binders or other ingredients, with excellent elasticity and flexibility, the maximum temperature up to 1600 ¡æ. They oxidizing atmosphere, the neutral atmosphere, the long-term bear this temperature, still maintain their original toughness, strength, flexibility and fiber structure, and non-residue ball, can be used by a variety of high-temperature industrial furnaces hot face lining paste, has a special significant insulation performance .

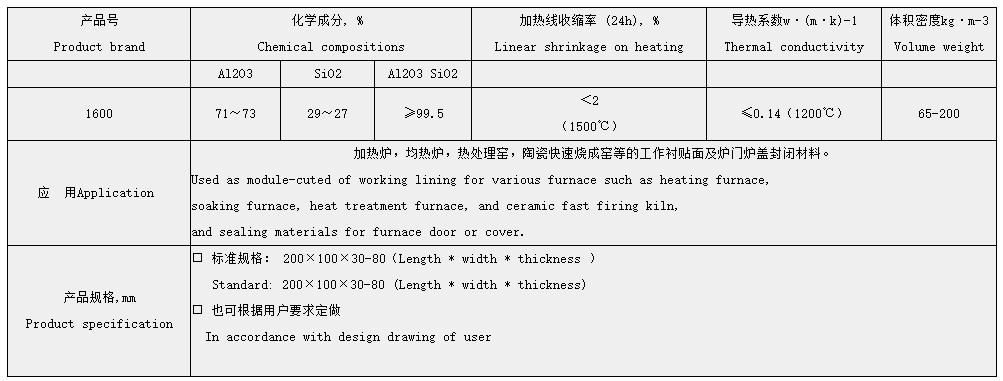

Product specification

Application

Heating furnace, soaking furnace, heat treatment kiln, ceramic rapid firing kiln, etc. working lining veneer and furnace door and cover sealing material.

Product specification

¡¡ Standard: 200¡Á100¡Á30-80 (Length * width * thickness)

¡¡¡¡

In accordance with design drawing of use

With the continuous improvement of the prosperity of the high-temperature refractory fiber industry, there have been some "three-no" manufacturers or companies without production capacity, quality assurance, and after-sales service in the market, relying on the knowledge of high-temperature ceramic refractory fibers by some heat treatment users It is not very comprehensive. Some heat treatment users are less aware of the risk and safety of the application of high-temperature ceramic refractory fibers, and through online publicity, they are induced to heat treatment users by means of low prices, and use low-temperature resistant products as resistant products. High temperature grade, the low-quality polycrystalline mullite fiber veneer block is used as high-quality, and sold to heat treatment users. High-temperature fibers (polycrystalline mullite (alumina) fibers) have relatively high production process control requirements. Among them, glue making: gel, sol, fiber formation: hot air temperature, material pressure, speed, drying, medium temperature heat treatment , Process data such as high temperature heat treatment temperature and time must be accurately controlled, otherwise severe shrinkage, chalking, cracks, falling off of the fiber lining will occur after use, resulting in fire, which will not only damage the equipment of the industrial furnace, but also cause the safety of the industrial furnace Production problems have brought considerable losses to heat treatment users.

Address: No.43, Xiyuan Road, Luoyang, Henan Province, China.